Reality Capture in VDC Introduction

Dr. Will Ikerd, PE, PhD

Director of Research & Education, BIMForum Global

Feb. 2024

Introduction

The following is a short introduction to Virtual Design and Construction terms that include the field of Reality Capture (RC) and Virtual Reality (VC) / Simulation with Modeling in the building industry. Future articles will look at the use of RC in various domains of the built environment.

Virtual Reality (VR) / Simulation with Modeling

Virtual Reality (VR) in the building design and construction industry refers to the use of computer technology to create a simulated, three-dimensional world that a user can manipulate and explore while feeling as if they were in that world. Simulation in the building industry if the process of using modeling to simulate the built environment. The simulated model is what is seen in VR. Here are some key applications of VR & Simulation in this industry:

- Design Visualization: VR allows designers and architects to create 3D models to help stakeholders see the building before it is built. This helps in getting the fine details just right by putting them in the room they’re designing.

- Improved Collaboration: VR can bring remote teams together by virtually placing them into the same space. This facilitates collaboration between on-site and off-site teams.

- Design Review and Support: VR improves stakeholder engagement by giving design teams the ability to present a realistic representation of a design.

- Construction Planning and Monitoring: VR can be used to improve construction planning and monitoring.

- Training and Safety: VR can also be used for training purposes, providing a safe and controlled environment for workers to learn new skills.

- Cost and Time Savings: By using VR in the design process, the construction phase of each project can save time and money.

As VR tech becomes more refined and available, it’s expected to be part of nearly every aspect of the construction process.

Augmented Reality (AR)

Augmented Reality (AR) is a technology that overlays computer-generated objects into the user’s physical environment, creating an interactive experience. In the building industry, AR has been used to enhance various aspects of the construction process:

- Project Planning: AR can layer several details and elements onto a building plan, providing stakeholders with an in-depth understanding of the project.

- Project Presentation: AR technology can be used in project presentations, allowing clients to visualize the final product in a more immersive way.

- Progress Capture: AR can be used to track the progress of a construction project, providing real-time updates and visualizations.

- Enhanced Collaboration: AR can maximize teamwork and collaboration by allowing all team members to visualize and interact with the same digital model.

- Safety Improvement: AR can improve safety on building sites by providing workers with real-time information and warnings.

- Training: AR can be used for construction training, providing a safe and controlled environment for workers to learn new skills.

AR is expected to see strong growth in the Architecture, Engineering, and Construction (AEC) industry over the next 5 to 10 years as the technology matures and construction firms undergo digital transformations. This will be a dynamic time from when this article is being posted in 2024.

Mixed Reality (MR)

Mixed Reality (MR) is a technology that combines real-world objects with digital content interactively and in real-time. It’s called “mixed” reality because it uses immersive technology to combine virtual and real settings, allowing users to perceive the current space overlaid with holographic data from a 3D model.

In the building design and construction industry, MR has several applications:

- Virtual Replica Creation: MR gives architects, designers, engineers, project managers, and service providers an unmatched capability of creating a virtual copy of what they are planning to build. They can walk around the structure and see how it will appear once it is built.

- Design Flaw Detection: Such a virtual tour allows for the early detection of design flaws, resulting in high cost and time savings.

- Improved Collaboration: MR technologies improve information flow and make work more efficient. A solution that integrates both hardware and software facilitate the collaboration of both on-site and off-site teams.

- Task Visualization: Crews can see exactly what task to accomplish with rapid feedback.

- Training: MR can be used for construction training, providing a safe and controlled environment for workers to learn new skills.

Mixed Reality (MR) is a technology that merges the physical and digital worlds, creating new environments where these elements can interact in real time. This technology, which lies somewhere along the “Virtuality Continuum” established by Paul Milgram in 1994, is transforming the way the construction industry receives and interacts with information.

MR allows professionals in the construction industry, such as architects, designers, engineers, and project managers, to create a virtual duplicate of their planned construction. This virtual tour enables early detection of design flaws, leading to significant cost and time savings.

The technology is intuitive to use as it mimics real life, but without the constraints of the physical world. It provides building industry teams with clear tasks and immediate feedback.

As technology advances, MR is expected to become an essential tool for construction projects by eliminating the limitations of computer screens, bulky equipment, and scattered information. The future of construction could see empowering hands-free data through MR.

Reality Capture (RC)

Reality capture in the building design and construction industry refers to the process of capturing, documenting, and analyzing the real-world conditions of a construction site or existing building. It uses innovative technologies to transform construction processes. Here are some key aspects of reality capture:

- Data Collection: Reality capture can leverage laser scans, drone images, smartphone photos, or high-resolution 360° images. This data is then uploaded to the cloud.

- Virtual Walkthrough: Once the data is uploaded, project stakeholders can virtually walk through the jobsite from anywhere in the world to see site conditions in near-real time and identify issues quickly.

- Efficiency and Savings: Reality capture can significantly streamline many processes, generating significant cost savings on single projects or multiple projects across an entire company. It can reduce travel by as much as 50%, improve communication, strengthen project management capabilities, and enhance quality assurance/quality control.

- Versatility: Reality capture can be performed with various devices, including cameras on drones, 360° cameras, iPhone and Android mobile phones, LiDAR scanners, and even robots.

- Digital Twin Creation: Reality capture enables builders to create a highly accurate and comprehensive digital replica (or digital twin) of physical spaces and structures in near-real time.

In essence, reality capture enhances accuracy, efficiency, safety, and communication throughout the entire construction process, from initial design to project completion.

Laser Scanning (LiDAR – Light Detection and Ranging)

LiDAR, which stands for “Light Detection and Ranging,” is a form of three-dimensional mapping technology. It’s often referred to as “laser scanning” or “LiDAR radar.” LiDAR creates 3D maps of physical space by measuring precise distances and spatial relationships between objects and features within an environment.

LiDAR is similar to RADAR (Radio Detection and Ranging), but it uses laser pulses instead of microwaves. The data generated by LiDAR is far more detailed, allowing for the creation of highly accurate 3D virtual replicas of physical spaces.

In the building industry, LiDAR 3D scanning technology offers numerous benefits:

- Accurate spatial data capture: LiDAR can accurately measure and map the details of a construction site or a building, providing valuable data for planning and design.

- Enhanced planning and design: With the detailed 3D maps created by LiDAR, architects and engineers can plan and design more effectively.

- Safe point cloud scanning: LiDAR scanning is non-intrusive and safe, making it ideal for scanning busy construction sites.

- Efficient maintenance and facility management operations: The detailed data provided by LiDAR can be used for efficient maintenance planning and facility management.

- Reducing rework: LiDAR can help identify any mistakes early in the design to construction phase, preventing expensive rework.

Overall, LiDAR is a powerful tool that is transforming the construction industry by providing unparalleled detail and accuracy in spatial data capture.

Photogrammetry

Photogrammetry is the science of reconstructing objects and environments in the physical world through photographs. It involves taking photos of an object or environment from different angles and using these images to generate reliable measurements. By taking photos from various positions and angles, teams can develop three-dimensional coordinates to accurately measure the depth and distance of points in relation to one another. At this time in 2024, tolerances for photogrammetry are not as tight as the tolerance of common LiDAR Laser Scanning. Additionally, photogrammetry equipment is typically less expensive and is a lower cost to deploy than LiDAR Laser Scanning.

In the building industry, photogrammetry has several applications:

- Site analysis and surveying: Photogrammetry is often used to rapidly survey construction sites, even before construction begins.

- As-built documentation: Photogrammetry transforms images and videos into accurate, “as-built” models of a structure or scene.

- Clash detection and coordination: Photogrammetry can help detect and coordinate any clashes in the design or construction phase.

- Remote project monitoring and planning: Photogrammetry can be used for remote project monitoring and planning, with or without 4D scheduling.

- Facility condition assessment: Photogrammetry can be used for the condition assessment of existing structures and infrastructure.

Overall, photogrammetry has revolutionized the construction industry, offering many applications and significant benefits. This technology enhances efficiency, accuracy, and safety in construction projects, from site surveys and mapping to quality control and progress monitoring.

Drone Capture (Unmanned Aerial Vehicles – UAVs)

Drone capture, also known as drone surveying, involves the use of unmanned aerial vehicles (UAVs) equipped with high-definition cameras to capture detailed visuals of construction sites. Here are some ways drone capture is used in the building industry:

- Topographic Mapping and Land Surveys: Drones can map vast quantities of land quickly and easily, providing detailed 3D imagery of the project site and surrounding area. This helps keep the project on schedule and on budget and ensures accuracy before the project is initiated.

- Equipment Tracking: Drones can do a flyover and quickly assess whether the equipment is where it needs to be. They can also quickly recognize if a piece of equipment that should be terminated is still on-site, preventing expensive accidental extension charges.

- Safety Inspections: Drones can identify potential hazards, such as structural weaknesses, unstable scaffolding, or equipment malfunction, in real-time.

- Progress Monitoring: Drone photos, videos, and imagery are used to track building progress and provide real-time updates.

- As-Built Documentation: Drones transform images and videos into accurate, “as-built” models of a structure or scene.

The use of drones in construction has grown briskly in recent years. Their aerial vantage point and data collecting abilities make them a viable tool, offering benefits ranging from on-site safety to remote monitoring. As the industry grows and construction projects become more complex, the use of drones in construction will continue to skyrocket.

Level of Development / Detail (LOD)

This is a construct for defining the reliability of information for element in a BIM. It is commonly a grading scale of 100, 200, 300, 350, 400, and 500. Refer to BIMForum.Global/LOD for more information on this topic.

Level of Acceptance (LOA)

This is a construct for reality capture that addresses both the tolerances and measurement densities of field collection of building element information. This is normally in the form of measurements and images. The type of information is commonly geometric measurement with technology such as laser scanning (Light Detection And Ranging – LiDAR), however LOA can address other forms of reality capture such as temperature, vibration, sound, moisture, etc. using other technologies. Refer to BIMForum.global/LOA for additional information.

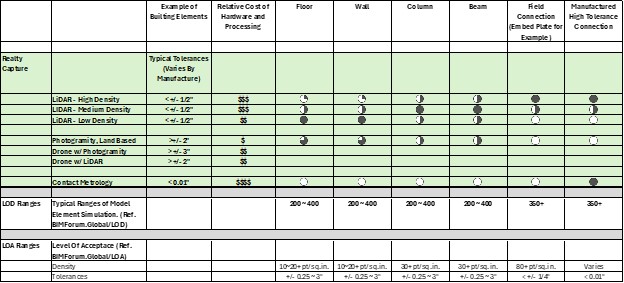

Qualitative Reality Capture Reference Table

The following table provides a qualitative comparison the technologies.

Note: The circles indicate recommend uses of the various reality capture methods for building elements. The recommended uses vary from not recommended (empty circle) to most common use (filled circle) in the table above. All information is relative and qualitative. Please refer to specific manufactures for detailed quantitative information for your particular use case.